Task: Continuous monitoring of load caused by concrete on temporary supportive construction (PIZMO)

Aim: To control the structural health stability and provide the safety assurance of PIZMO system

Project: D-1 Jánovce – Jablonov, Slovakia, Highway Bridge (under construction), August 2013

Measuring method: Continuous (automated measuring system)

Sampling rate: 30 seconds (2x per minute) per each sensor

Number of samples: 1229 per each sensor

Duration of monitoring: 10 hours (starting at 05:40 till 15:40) Number of sensors: 47 (41x strain, 6x temperature)

Type of sensors: FBG sensors: MS-02 (mountable strain sensor) and modified TP-02 (mountable temperature sensor)

Interrogators: FBG-Scan 816 and MicronOptics sm125

Weather conditions: morning 7°C, sunny with partial cloudy weather, max temperature 32°C

Details: The continuous load is created by pumping of around 480m3 concrete on the top of the PIZMO system to build the highway bridge deck. This process takes around 10 hours and provides enough measuring data to evaluate the increase of load on the PIZMO system. There have been selected 6 individual pillars of the PIZMO system and additional horizontal and cross-oriented elements between pillars to be monitored. This, over the entire time of monitoring, has provided enough data for static analysis. The extent of this report doesn’t allow to present all measured data, following information are selected as representative measured and evaluated data. The load has been calculated using Hooke’s law and the known elasticity modulus of the steel. As the tensile stress the relative elongation (compression) has been measured based on the FBG principle.

The MS-02 sensor parameters:

- Measuring range: ±5000µɛ

- Resolution: 0.83 µɛ

Advantages of the measuring system:

- Repeatable monitoring

- Easy and flexible access cable topology

- Automated Temperature compensation

Measured results:

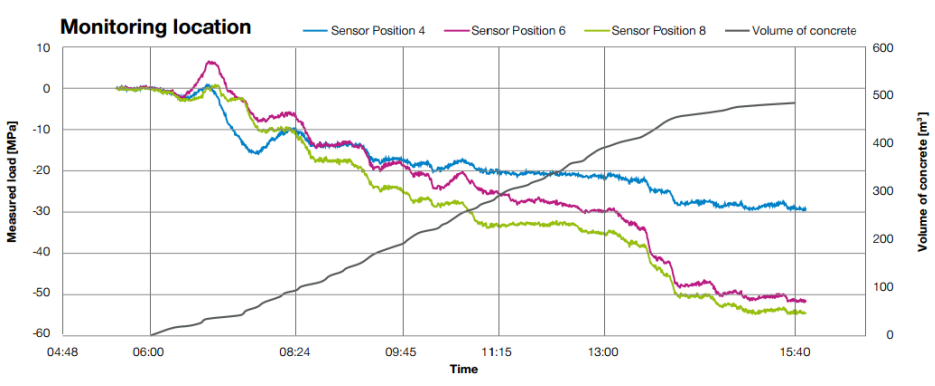

As shown on the below figure the progress of the load (3 individual vertically mounted sensors) on the pillar has correspondingly risen with the amount of the concrete being pumped on the top of measured system. All three load curves are already temperature compensated based on measured temperature profile, because the task was to measure the response of the PIZMO system based only on the concrete mass load. Measured values of maximum load varied between each measured pillars as the construction itself distributed the load continuously, however all measured values remained in accordance with static calculation.