- Geo-technical SHM

- Our monitoring systems or individual sensors have been installed over dozens of large and mid-size civil structure objects around the world. This includes:

- Tunnels

- Sewers

- Mines

- Piles

Our Geo-technical SHM products

Type: Fiber Bragg Grating-based Anchor Load Cell, specifically designed to be used as an anchor loadcell in applications as bolt constructions, pre-strained constructions, quay walls etc.

Measurement range: 50-240 kN

Application: Bolt constructions, pre-strained constructions, quay walls

Temperature compensation: Integrated

D-04 is an improved version of former D-01 and D-02 sensors.

Type: customizable measuring range from 0-100mm Displacement sensor

Application: Application-based

Installation method: Custom

Temperature compensation: Integrated in the sensor body

Type: Embeddable strain sensors

Application: Strain measurement inside concrete structures.

Installation method: Embeddable

Pre-strain setup: At factory

Temperature compensation: Through external temperature sensor

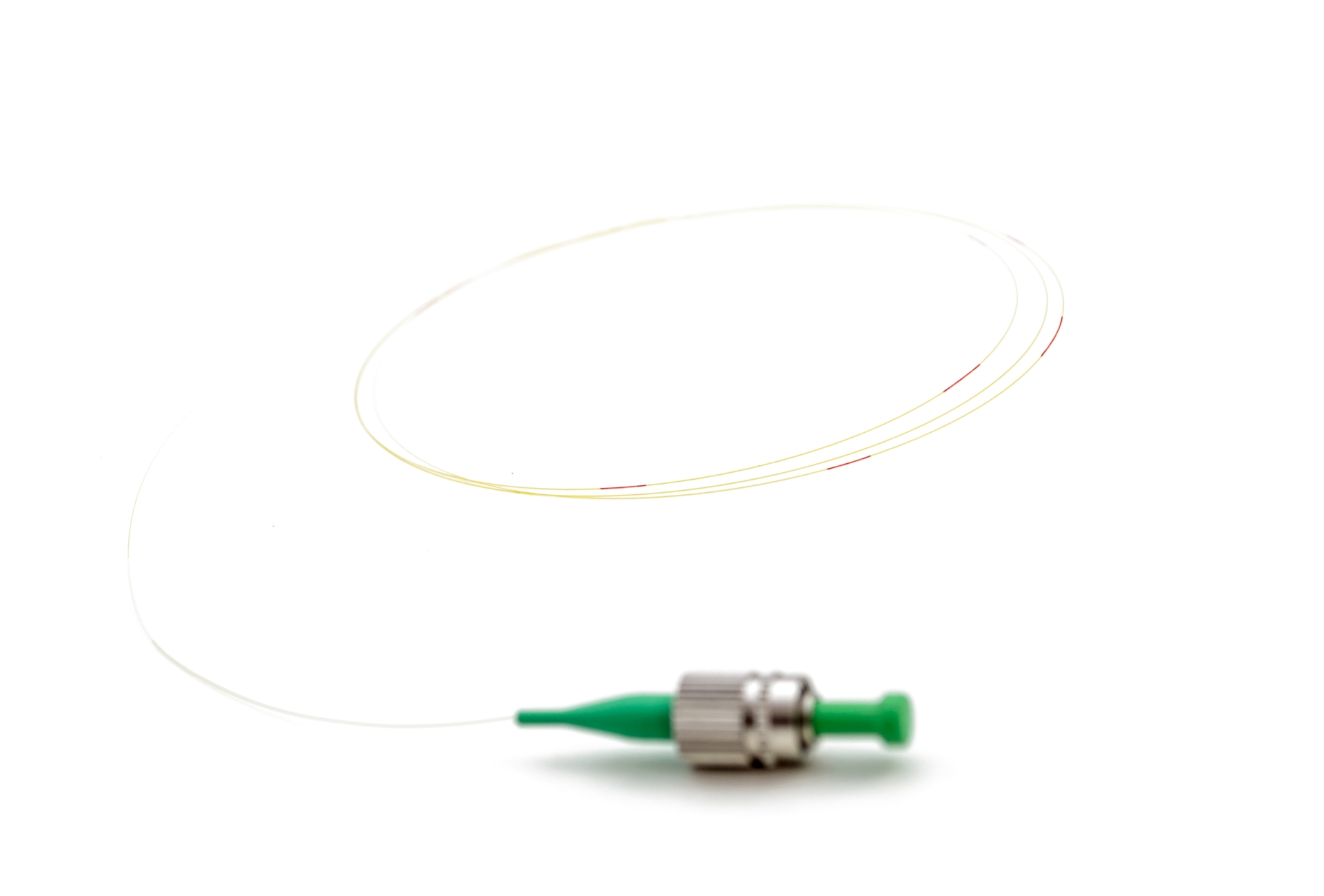

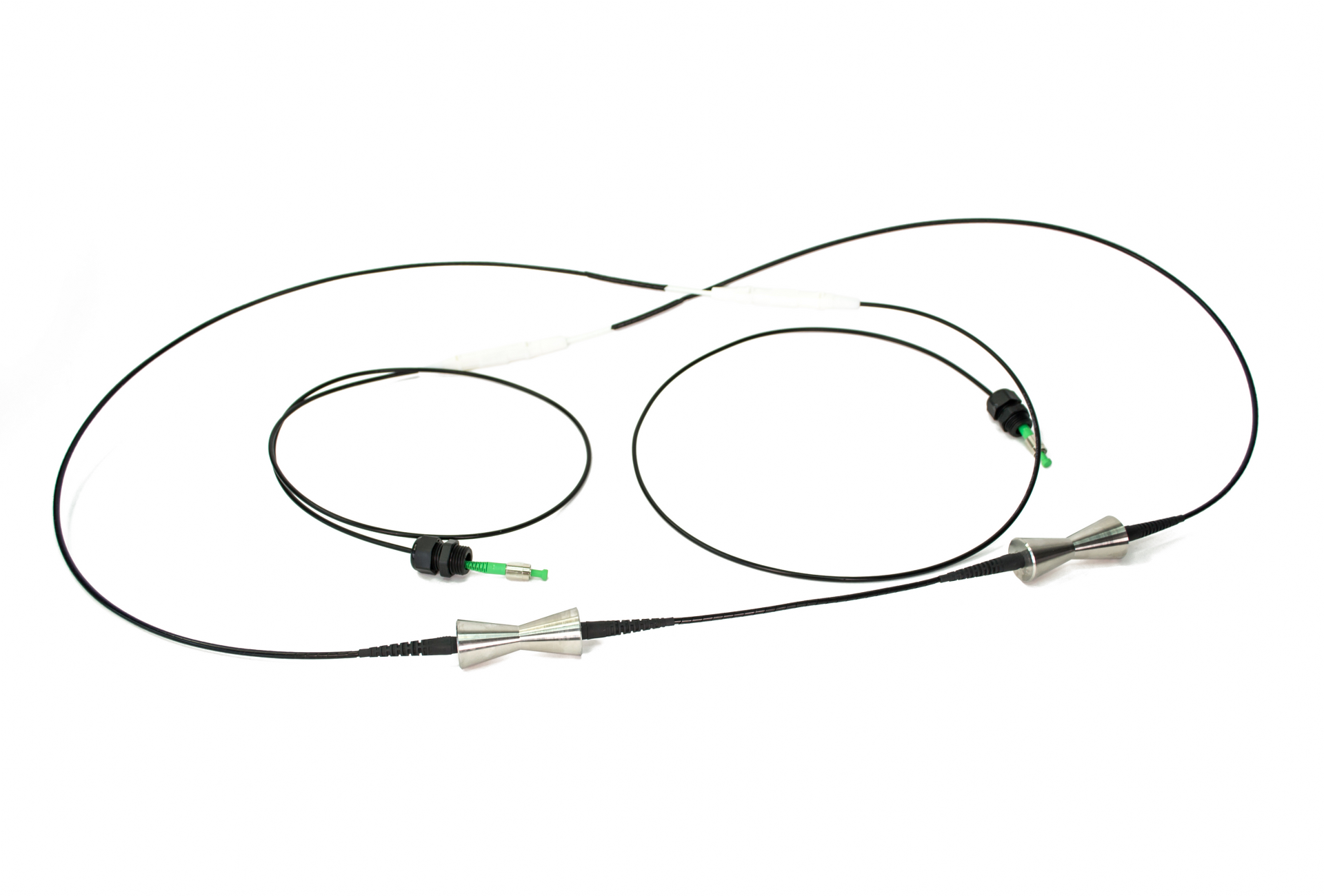

Type: FBG fiber array sensor

Application: Surface mountable

Installation method: Glue

Pre-strain setup: At installation

Temperature compensation: Through external temperature sensor

Type: GFRP fiber array sensor

Application: Concrete or grout embeddable, surface mountable

Installation method: Glue

Pre-strain setup: At installation

Temperature compensation: Through external temperature sensor

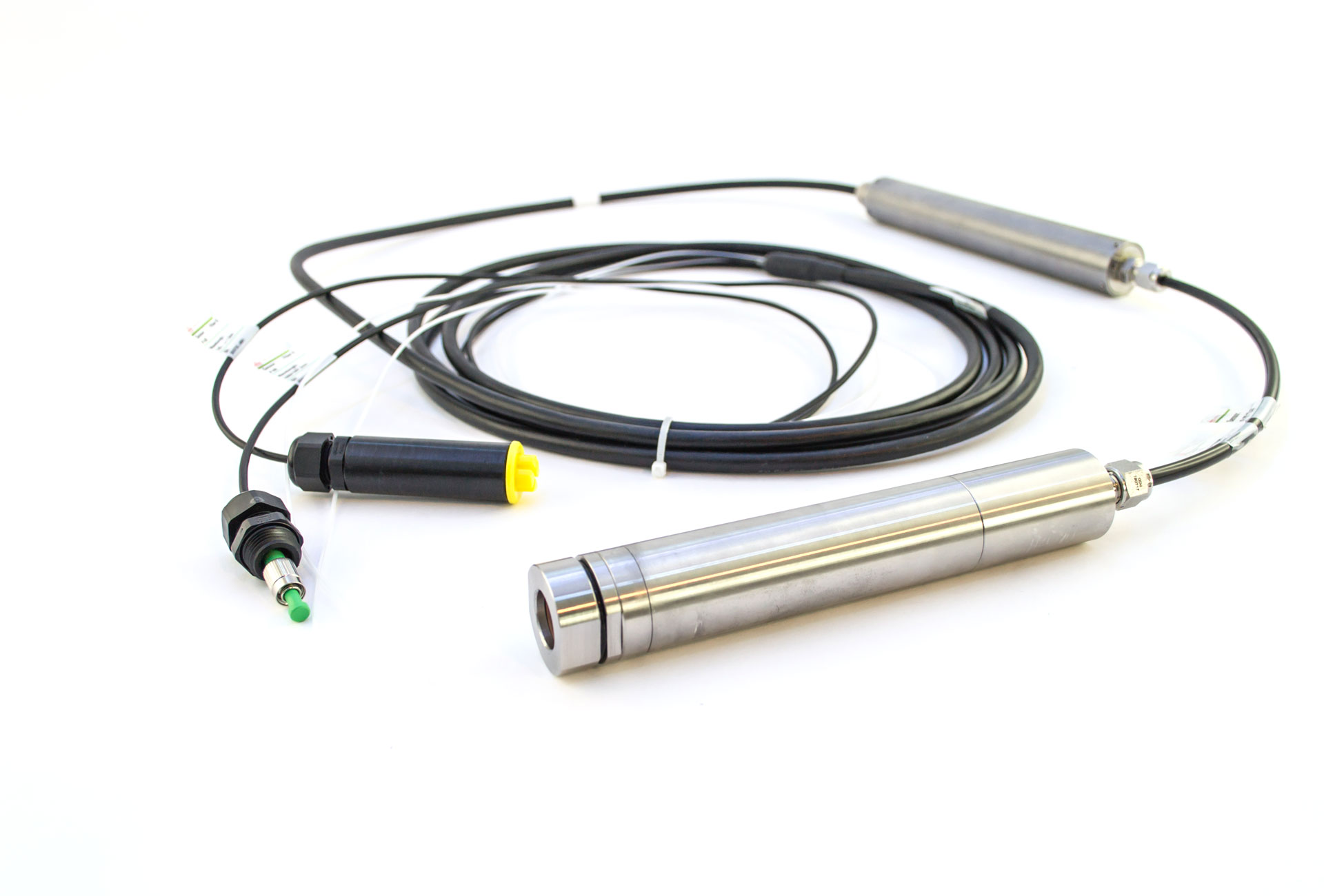

Type: Customable sensor for a wide pressure range (0-20 bar), IP68

Application: water height monitoring, hazardous environment monitoring, geotechnical, marine, etc.

Installation method: Mounting brackets – weldable, screwable

Temperature compensation: Integrated

Type: Short-gauge strain sensors

Application: Concrete or grout embeddable, surface mountable

Installation method: Mounting brackets – weldable, screwable

Pre-strain setup: At installation

Temperature compensation: Through external temperature sensor

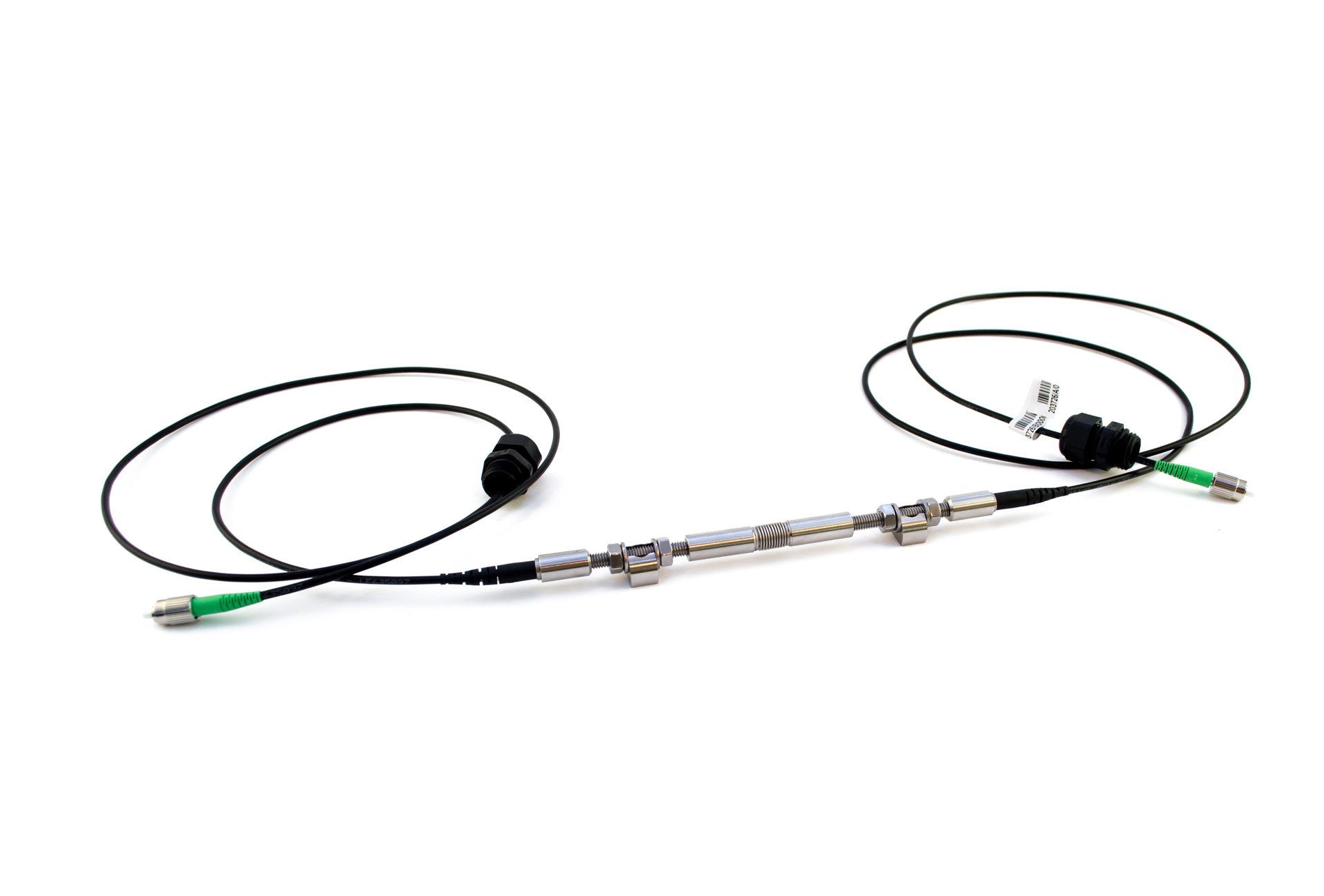

Type: Multiple-gauge strain sensor

Application: Concrete or grout embeddable, surface mountable

Installation method: Mounting brackets – weldable, screwable

Pre-strain setup: At installation

Temperature compensation: Through external temperature sensor

Type: Customable sensor for a wide pressure range (0-100 bar)

Application: hazardous environment monitoring, geotechnical, marine, etc.

Installation method: Mounting brackets – weldable, screwable

Temperature compensation: Integrated

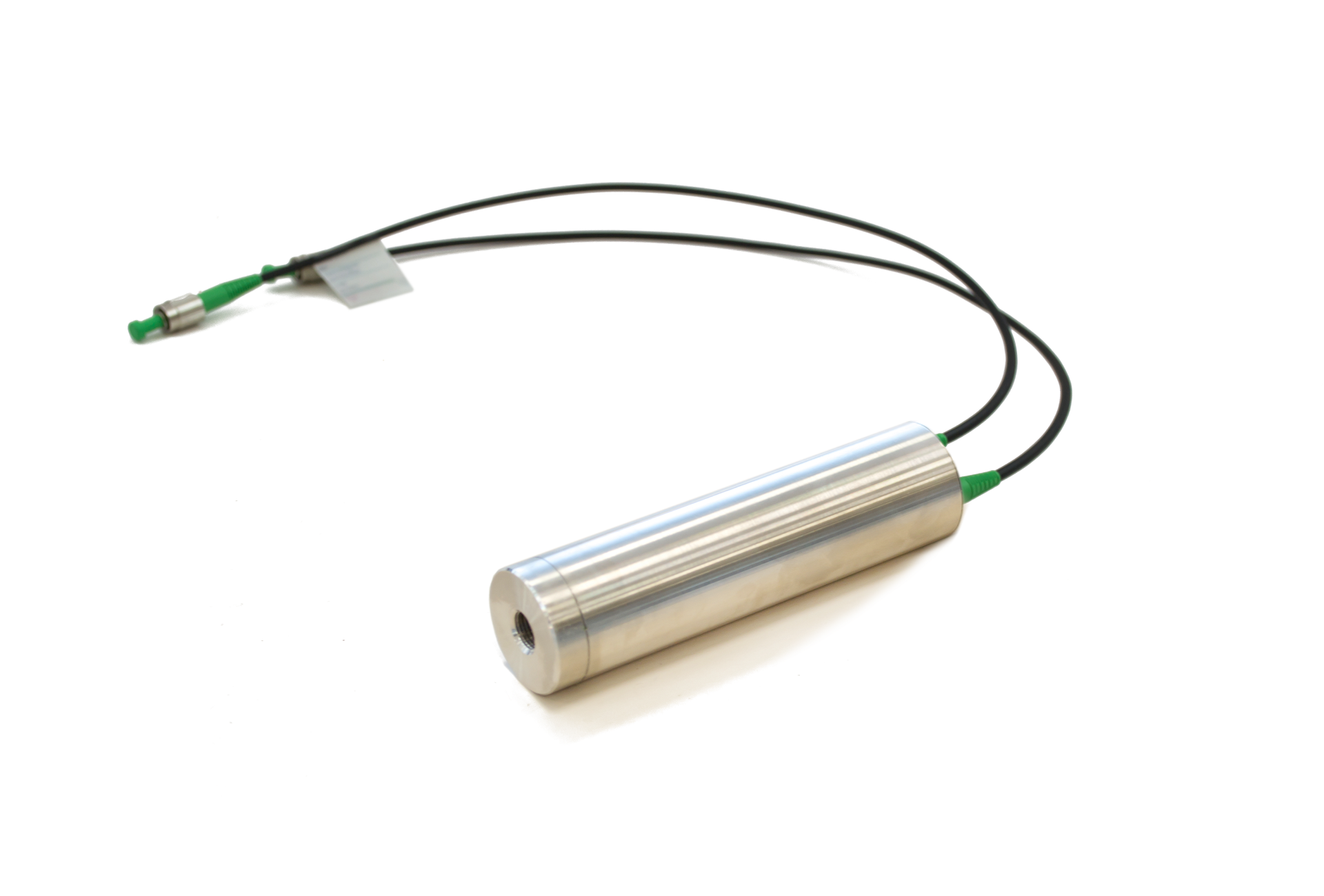

Type: Fiber Bragg Grating-based single-axis accelerometer, specifically designed to measure high acceleration values up to 200g.

Application: Can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: Integrated

Type: Fiber Bragg Grating-based single-axis accelerometer, specifically designed to measure acceleration values up to 30g with high sensitivity and large frequency bandwidth.

Application: Can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: External

Type: Fiber Bragg Grating based single-axis accelerometer, specifically designed to measure acceleration values up to 2g with unmatched sensitivity.

Application: Detection of ultra-low-level vibrations, can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: External

Type: Fiber Bragg Grating based single-axis tilt meter, specifically designed to measure long term angular variations of large structures.

Measurement range: 10° (±5°)

Application: Tilt changes detection. Can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: Integrated

Type: Fiber Bragg Grating based single-axis tilt meter, specifically designed to measure long term angular variations of large structures.

Measurement range: 30° (±15°)

Application: Tilt changes detection. Can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: Integrated

Type: Fiber Bragg Grating based single-axis tilt meter, specifically designed to measure long term angular variations of large structures.

Measurement range: 3° (±1.5°)

Application: Tilt changes detection. Can be mounted on different surfaces including walls, etc.

Installation method: Screws or using a mounting block

Temperature compensation: Integrated

Type: Directly embeddable strain sensor

Application: Strain measurement inside concrete structures

Installation method: Concrete embeddable

Pre-strain setup: No pre-strain adjustment is required during installation and setup

Battery power: 12V/3,35 Ah

Battery life: approx 4 hours

Nr. of power sockets: 1

Battery power: 12V/6,7 Ah

Battery life: approx 8 hours

Nr. of power sockets: 1

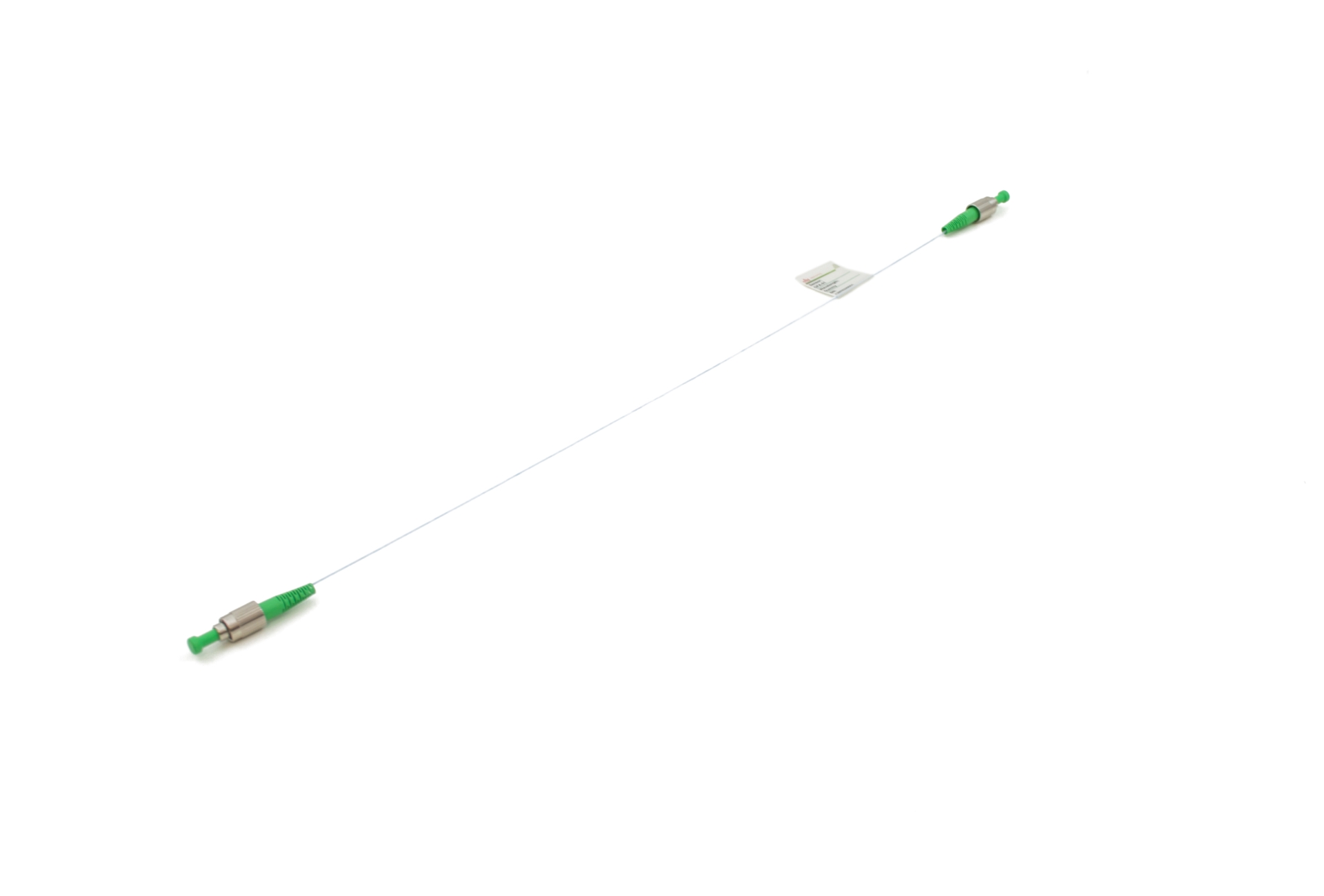

Type: Long-gauge strain sensors

Application: Concrete or grout embeddable, surface mountable

Installation method: Mounting brackets – weldable, screwable

Pre-strain setup: At installation

Temperature compensation: Integrated in the sensor body

Type: Static/Dynamic

Wavelength range: 80nm

Sampling rate: up to 5 kHz

Nr. Of optical channels: 1

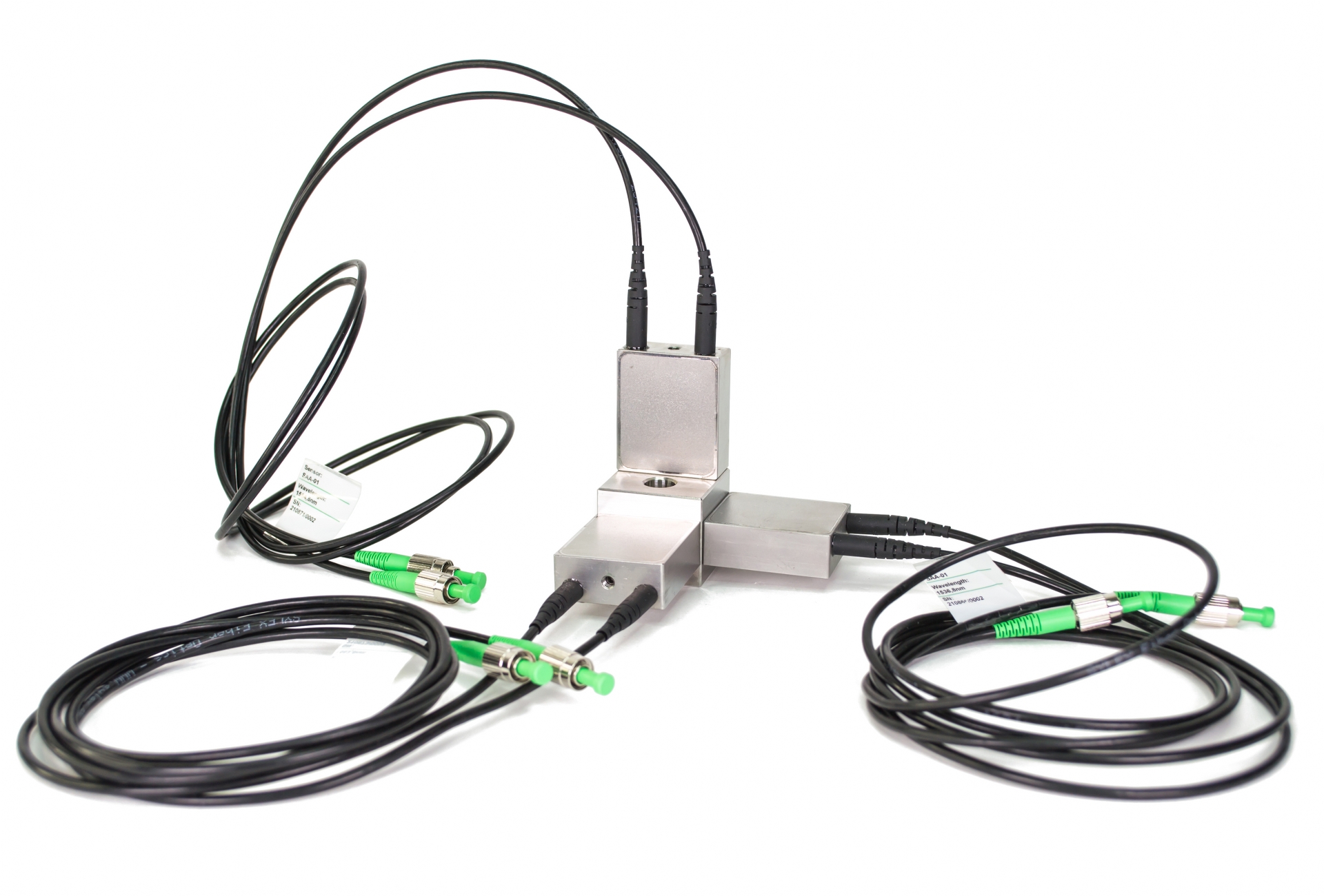

Type: Static

Wavelength range: 80nm

Sampling rate: Adjustable up to: 1Hz

Nr. Of optical channels: 4

Type: Static / Dynamic

Wavelength range: 80nm

Sampling rate: Adjustable up to: 900Hz

Nr. Of optical channels: 4

Type: Static

Wavelength range: 80nm

Sampling rate: Adjustable up to: 1Hz

Nr. Of optical channels: 16

Type: Static

Wavelength range: 80nm

Sampling rate: Adjustable up to: 0.5Hz

Nr. Of optical channels: 36

Type: Sewer deformation sensor

Application: Surface mountable

Installation method: Direct screwable

Pre-strain setup: At factory

Temperature compensation: Integrated in the sensor body

Type: Industrial PC

Communication: USB, LAN, HDMI, WiFi

OS: Windows 10

Compatibility: S-line Interrogators: Scan 800 (SCN-80) and Scan 400 (SCN-40)

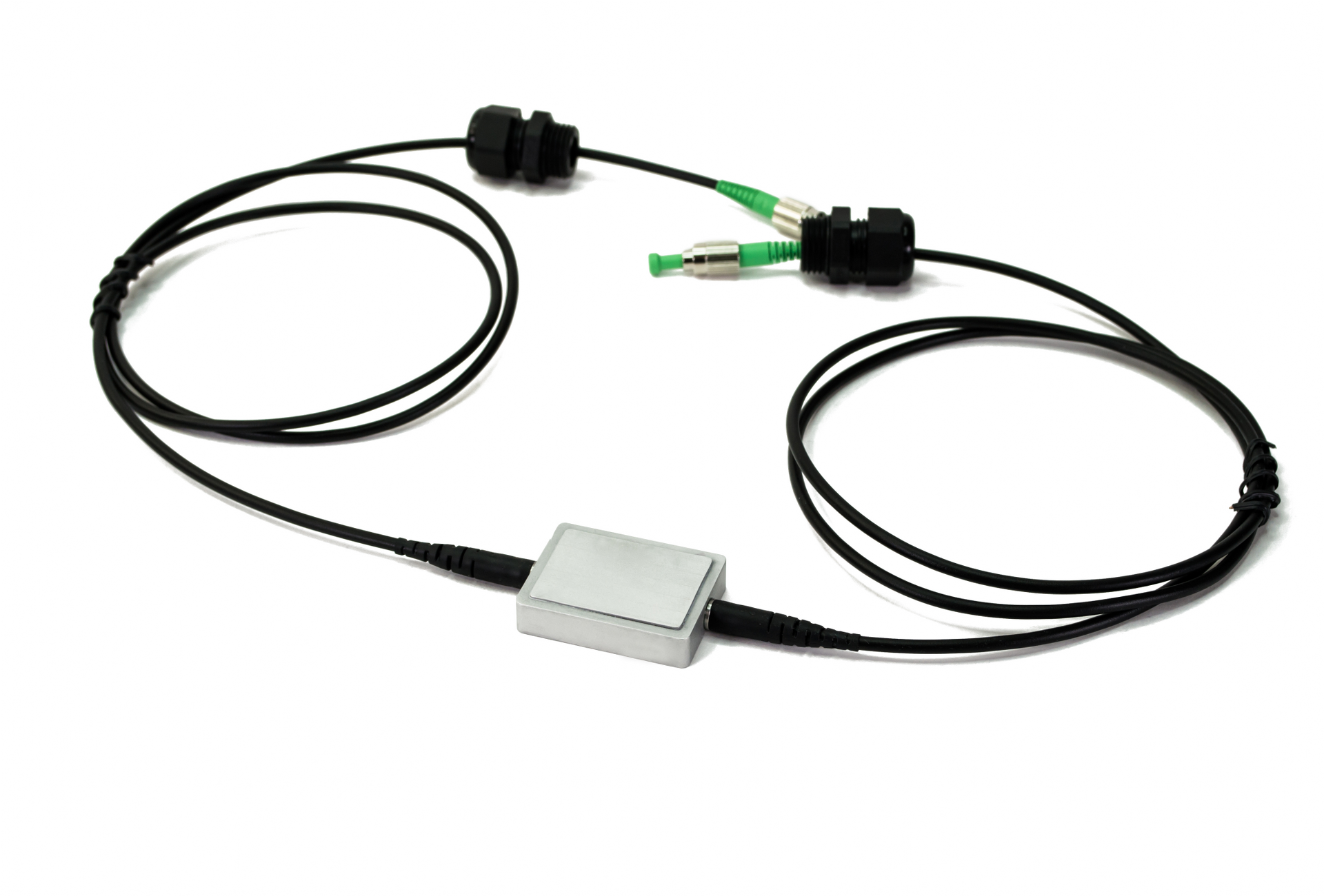

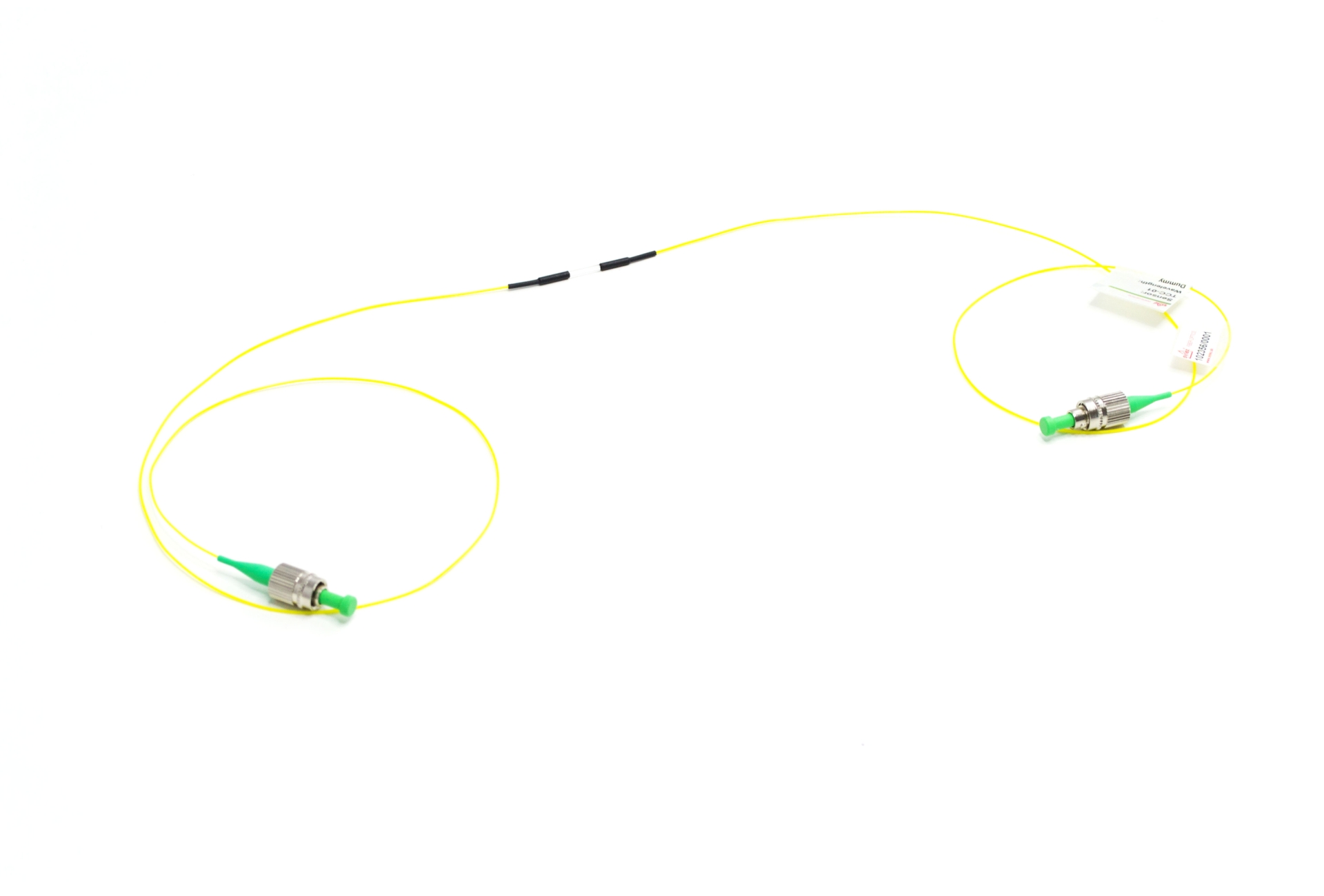

Type: Static / Dynamic

Matrix: 1×2

Compatibility: S-line Interrogators: Scan 800 (SCN-80), Scan 400 (SCN-40)

Compatibility: S-line Switches: 1×4 (SWD-04, SWS-04), 1×16 (SWS-16), 1×36 (SWS-36)

Type: Static / Dynamic

Matrix: 1×4

Compatibility: S-line Interrogators: Scan 800 (SCN-80), Scan 400 (SCN-40)

Compatibility: S-line Switches: 1×4 (SWD-04, SWS-04), 1×16 (SWS-16), 1×36 (SWS-36)

Type: Static / Dynamic

Matrix: 4×16 [4x(1×4)]

Compatibility: S-line Interrogators: Scan 800 (SCN-80), Scan 400 (SCN-40)

Compatibility: S-line Switches: 1×4 (SWD-04, SWS-04), 1×16 (SWS-16), 1×36 (SWS-36)

Type: Surface temperature sensor

Application: Temperature compensation or local temperature measurement

Installation method: Surface mountable – gluable or custom brackets

Type: Surface temperature sensor

Application: Surface temperature measurement, chemical and oil & gas applications

Installation method: Direct surface mounting

Type: Dynamic

Nr. Of optical channels: 4

Switching time: 50us

Compatibility: S-line Interrogators: Scan 800 (SCN-80)

Type: Static

Nr. Of optical channels: 4

Switching time: 60ms

Compatibility: S-line Interrogators: Scan 800 (SCN-80) and Scan 400 (SCN-40)

Type: Static

Nr. Of optical channels: 16

Switching time: 60ms

Compatibility: S-line Interrogators: Scan 800 (SCN-80) and Scan 400 (SCN-40)

Type: Static

Nr. Of optical channels: 36

Switching time: 60ms

Compatibility: S-line Interrogators: Scan 800 (SCN-80) and Scan 400 (SCN-40)

Type: Ruggedized temperature sensor

Application: Temperature compensation or local temperature measurement

Installation method: Concrete or grout embeddable, surface mountable

The previous generation of the product is TP-02

Type: Small multi-point temperature sensor chain

Application: Temperature compensation or multi-point temperature measurement

Installation method: Surface mountable – gluable