As technology goes forward, some inventions replace others and the replaced inventions become legacy products. This also applies for fibre optics. More and more companies are using BIMMF (bend-insensitive multimode fibre) nowadays and it is harder and harder to buy regular MMF (multimode fibre) because it is a legacy product. This is something that shouldn’t matter, but it does.

According to the new revision of IEC 61280-4-1: “When undertaking LSPM testing of A1-OMxa or A1-OMxb optical fibres, the launch cord can contain optical fibres of sub-division A1-OMXa or A1-OMxb (BIMMF).” This means that it doesn’t matter if you use MMF or BIMMF in a DUT (device under test). It is not even important if the master jumper used to evaluate the DUT has MMF or BIMMF. The only thing that matters is that both the DUT and master jumper have the same core size. But is there no difference? Does it not have to be taken into account if the master jumper has MMF or BIMMF? As a production company that has terminated more than 20 million connectors throughout its existence and has customers all over the world, we know that every fibre type and every connector has its own properties and behaviour. So we decided to look closer into this issue and see for ourselves whether or not it’s necessary to pay attention to fibre type in the DUT and in the master jumper. We have prepared several tests to understand the difference between MMF and BIMMF cables. There are several commonly used methods to check the quality of a terminated connector:

• Visual inspection

• Geometry

• IL measurement

All connectors used in the tests have passed the geometry evaluation according to the Telcordia GR326 standard for single-fibre connectors and the IEC 63267-3-31 standard for multi-fibre connectors, so we have decided to look at the MMF and BIMMF through visual inspection and IL measurement.

Visual inspection

Inspected product:

• LC/PC – SC/APC 50/125µm MMF simplex jumper 3.0m

• LC/PC – SC/APC 50/125µm BIMMF simplex jumper 3.0m

Inspection method:

• Inspection according to IEC-61300-3-35

Equipment used:

• VIAVI FVD-2400 Microscope

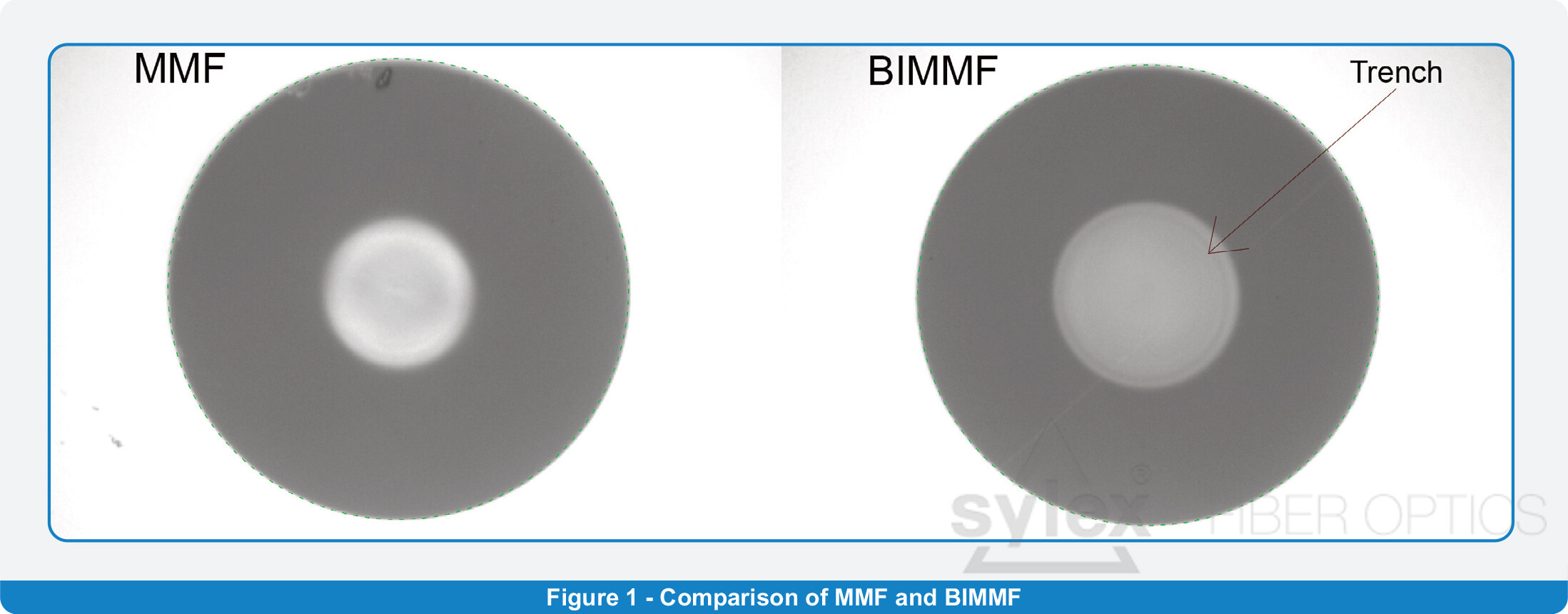

One of the easiest ways to spot the difference between these two types of fibres is visual inspection. The thin circle on BIMMF indicates the trench, a layer around the fibre core that has a lower refractive index than the core. Thanks to this, the higher modes are reflected back to the fibre core when the fibre is bent. Taking this into account in terms of measuring insertion loss (IL), a difference between MMF and BIMMF fibres are the leaky higher modes that are present in BIMMF fibre. The reference done before measurement of the DUT will equalise any differences between BIMMF and MMF fibre types used in master jumpers, but this equalisation can be easily disturbed when manipulating the master jumper and the DUT during measurement.

Measurement of insertion loss

Set of tests:

• LC/PC preterm measured according to IEC-61300-3-4 method B by MMF and BIMMF master jumpers

• MTP trunk measured according to IEC-61300-3-4 method B by MMF and BIMMF master jumpers

• LC/PC to MTP fanout measured according to IEC 61280-4-1 annex A, one cord reference method by MMF and BIMMF master jumpers.

LC/PC preterm measured by MMF and BIMMF master jumpers

Tested product:

• 48xLC/PC – 48xLC/PC 48F 50/125µm BIMMF preterm 13.0m

• 72xLC/PC – 72xLC/PC 72F 50/125µm BIMMF preterm 185.0m

Master jumper:

• LC/PC – SC/APC 50/125µm MMF simplex jumper 3.0m

• LC/PC – SC/APC 50/125µm BIMMF simplex jumper 3.0m

Measurement method:

• Measured according to IEC-61300-3-4 method B

Equipment used:

• JGR MS12001 system

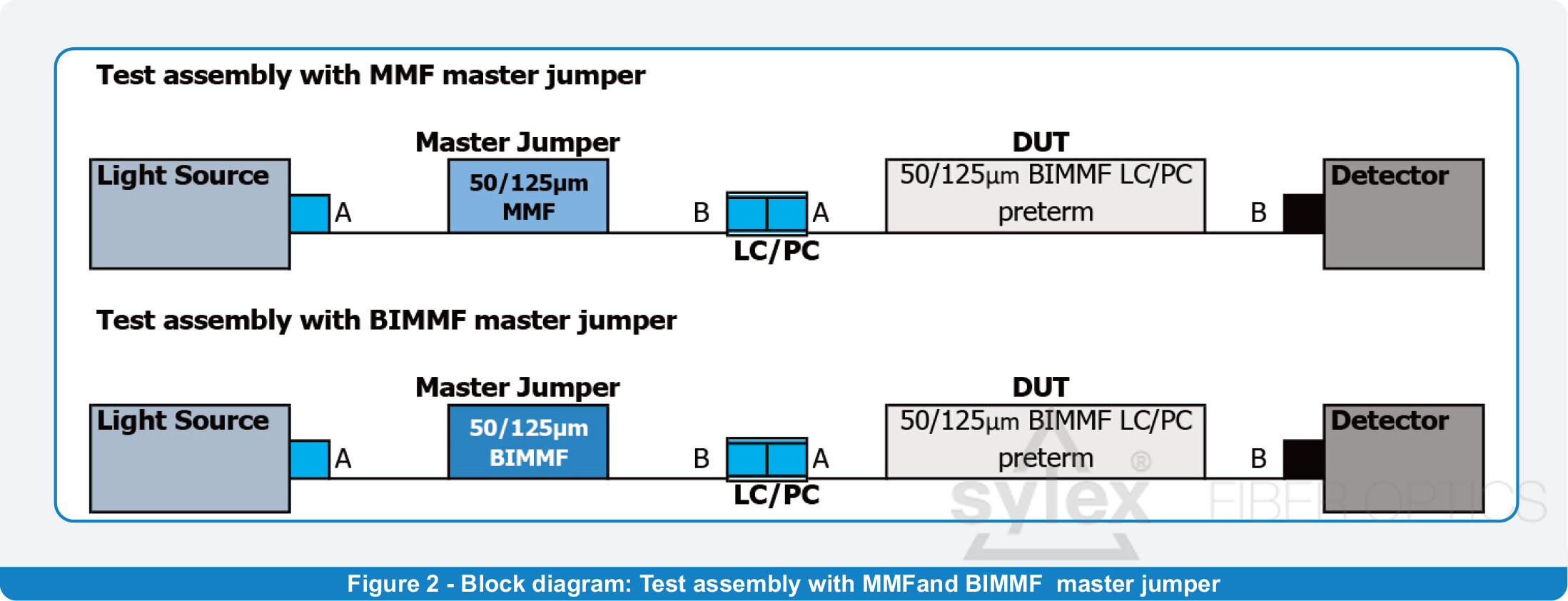

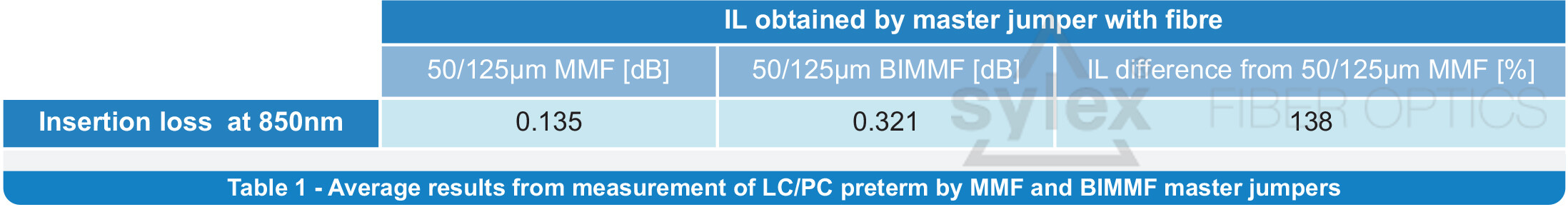

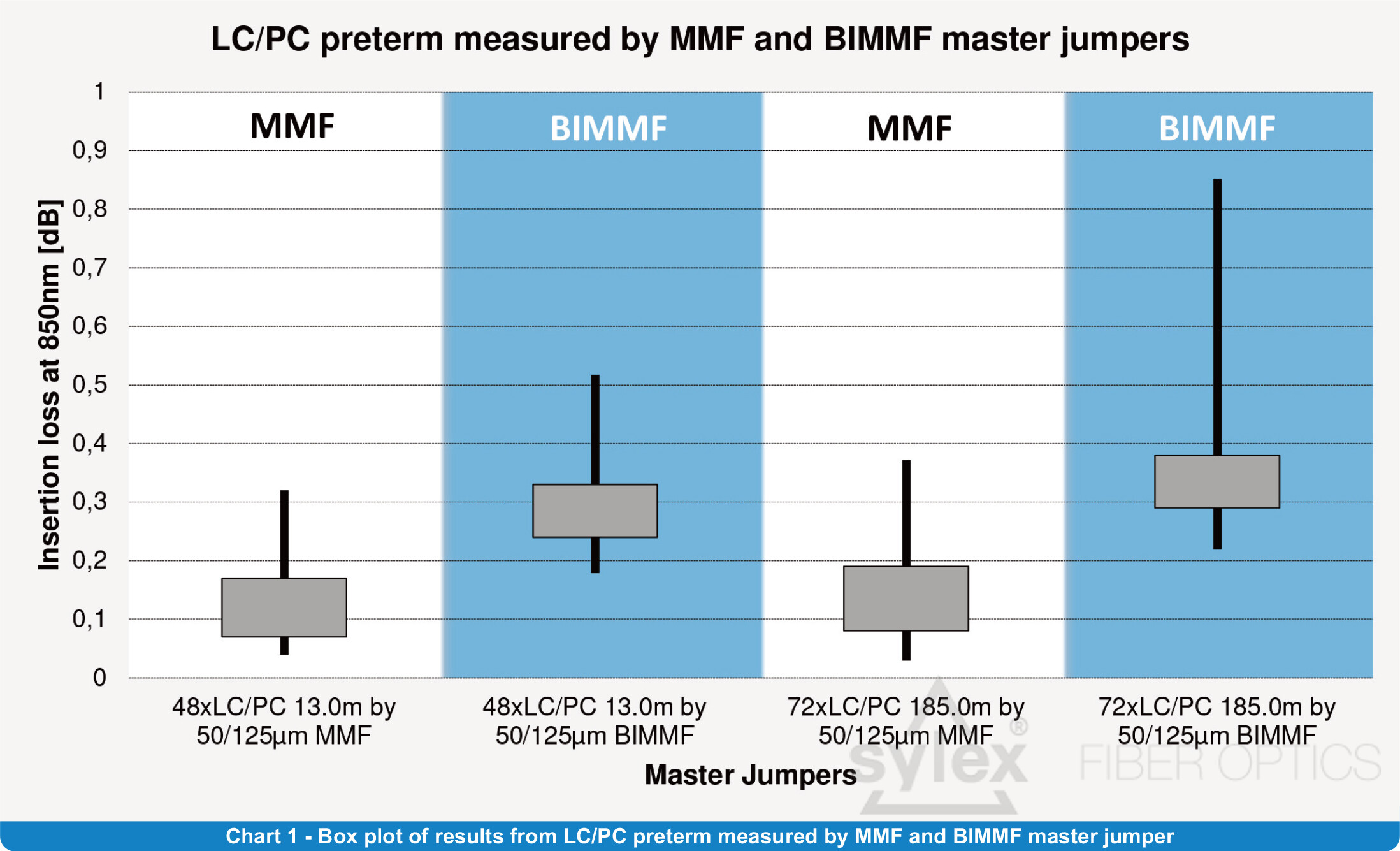

A visual inspection of the fibre cores in MMF and BIMMF shows that there is a difference between these cores. Around the BIMMF core is an extra layer surrounding the core. This layer prevents the light from escaping while bent. For this test an LC connector was chosen as one of the most common connector types. The LC connector was terminated on 50/125µm BIMMF. Two different fibre types were used in the master jumpers that were used for this test. One group of master jumpers was with 50/125µm MMF to represent legacy products and the other group was with 50/125µm BIMMF to represent fibres commonly used nowadays. The initial conditions stayed the same for all tests. That means that the measuring device, all adapters used to connect the DUT and master jumper together with the measuring device and all other factors that could affect the outcome of the test stayed unchanged. Almost 250 connectors were tested with each master jumper. The average value of all measurements obtained by MMF and BIMMF are shown in table 1. According to this, the best results were obtained by master jumpers with 50/125µm MMF. Values obtained by BIMMF are 138% higher than the value obtained by MMF. More detailed results are shown in chart 1, where it can be seen that although the dispersion of IL values obtained by MMF and BIMMF are comparable, all results obtained by BIMMF are higher than the ones obtained by MMF master jumpers.

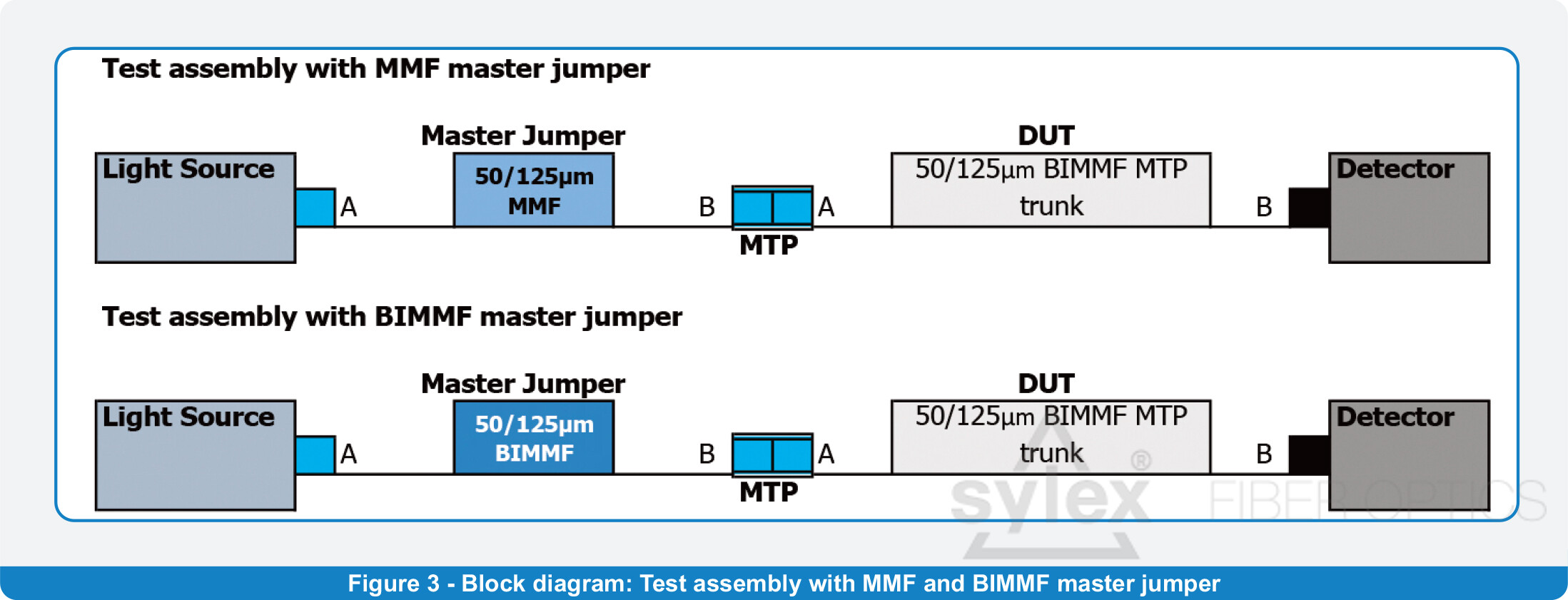

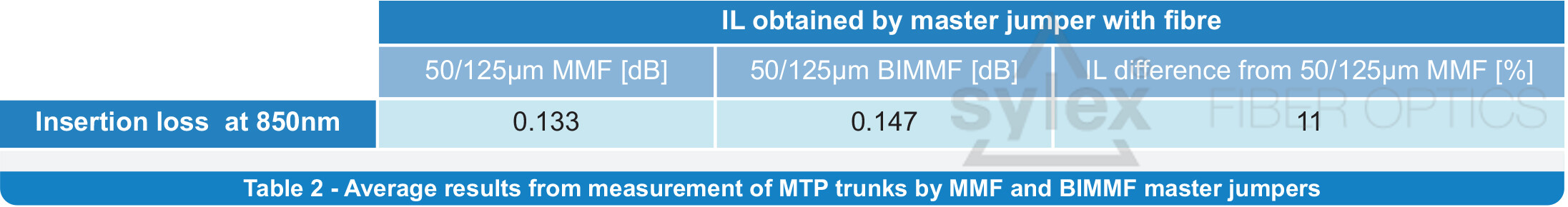

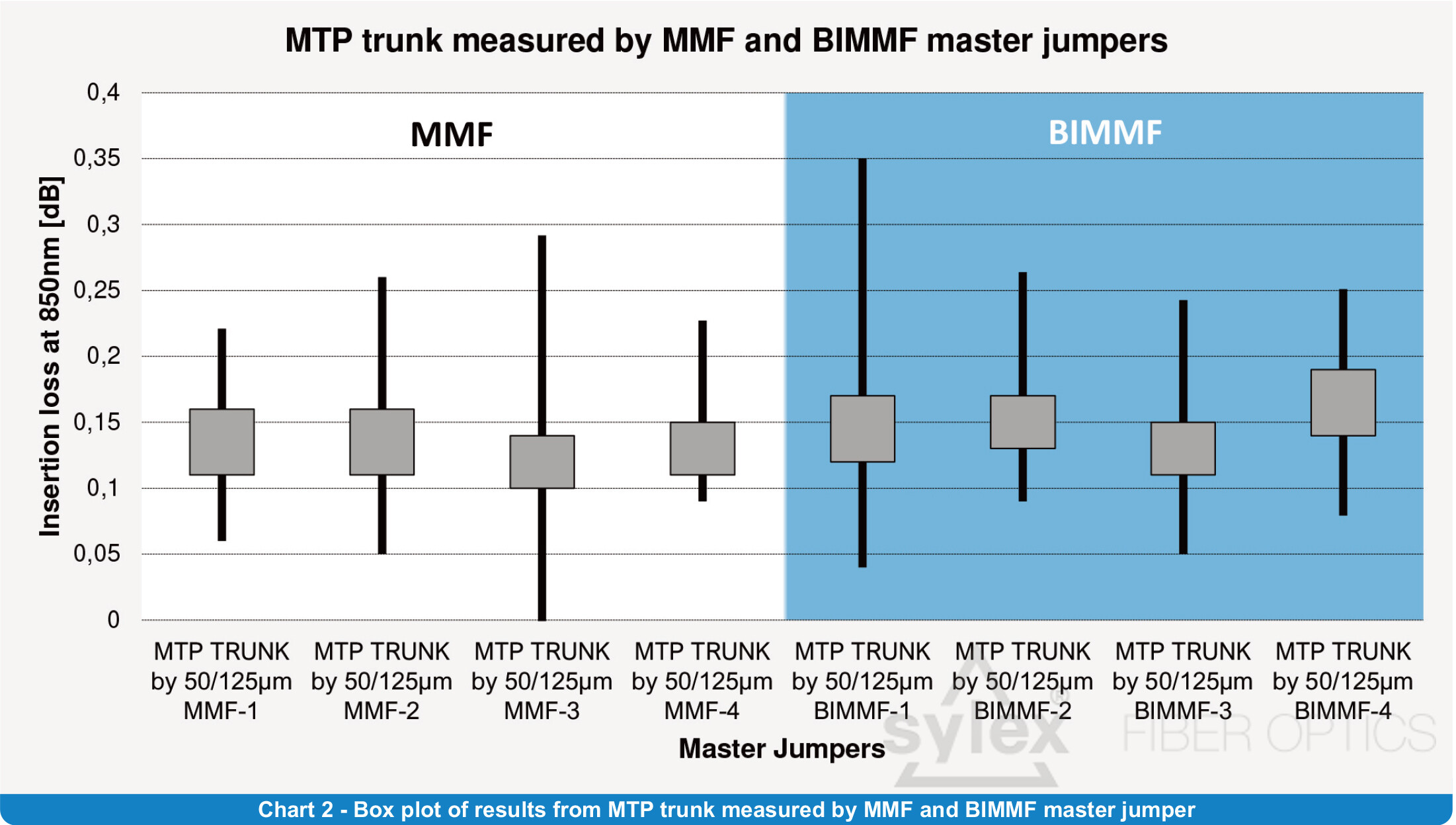

MTP trunk measured by MMF and BIMMF master jumpers

Tested product:

• 1xMTP(F) – 1xMTP(F) 12F 50/125µm BIMMF trunk Pol. B 20.0m

• 1xMTP(F) – 1xMTP(F) 12F 50/125µm BIMMF trunk Pol. B 29.0m

• 1xMTP(F) – 1xMTP(F) 12F 50/125µm BIMMF trunk Pol. B 32.0m

Master jumper:

• 1xMTP(M) – 1xMTP(M) 12F 50/125µm MMF trunk 3.0m

• 1xMTP(M) – 1xMTP(M) 12F 50/125µm BIMMF trunk 3.0m

Measurement method:

• Measured according to IEC-61300-3-4 method B

Equipment used:

• JGR MS12001 system

For this test an MTP connector was chosen as one of the most highly demanded connectors in datacentres. The MTP connector was terminated on 50/125µm BIMMF. Two different fibre types were used in the master jumpers that were used for this test. One group of master jumpers contained 50/125µm MMF, while the second group contained 50/125µm BIMMF. The initial conditions stayed the same for all tests. Almost 200 values were obtained with each master jumper. The best results were obtained by master jumpers with 50/125µm MMF, as seen in table 2. Values obtained by BIMMF are 11% higher than the value obtained by MMF. The detailed results are shown in chart 2. The dispersion of results obtained by MMF and BIMMF are comparable to each other. Insertion losses measured by BIMMF master jumpers were higher than the ones obtained by MMF.

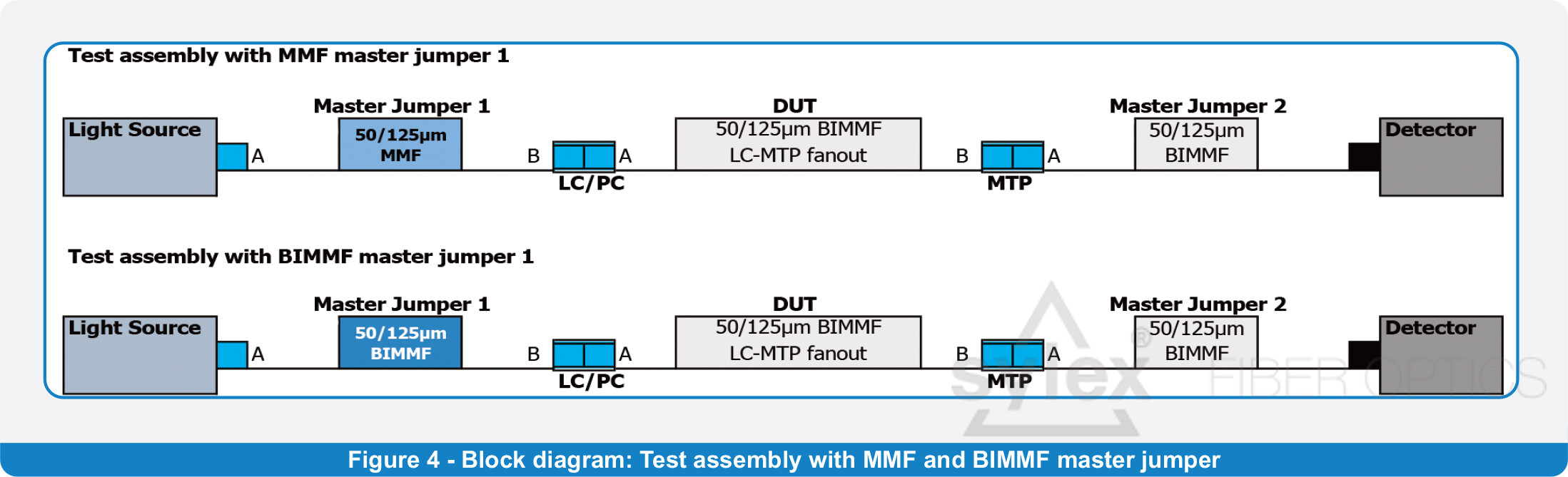

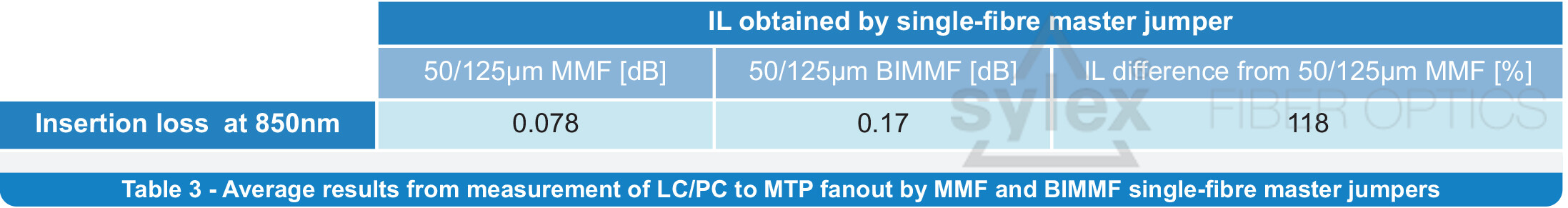

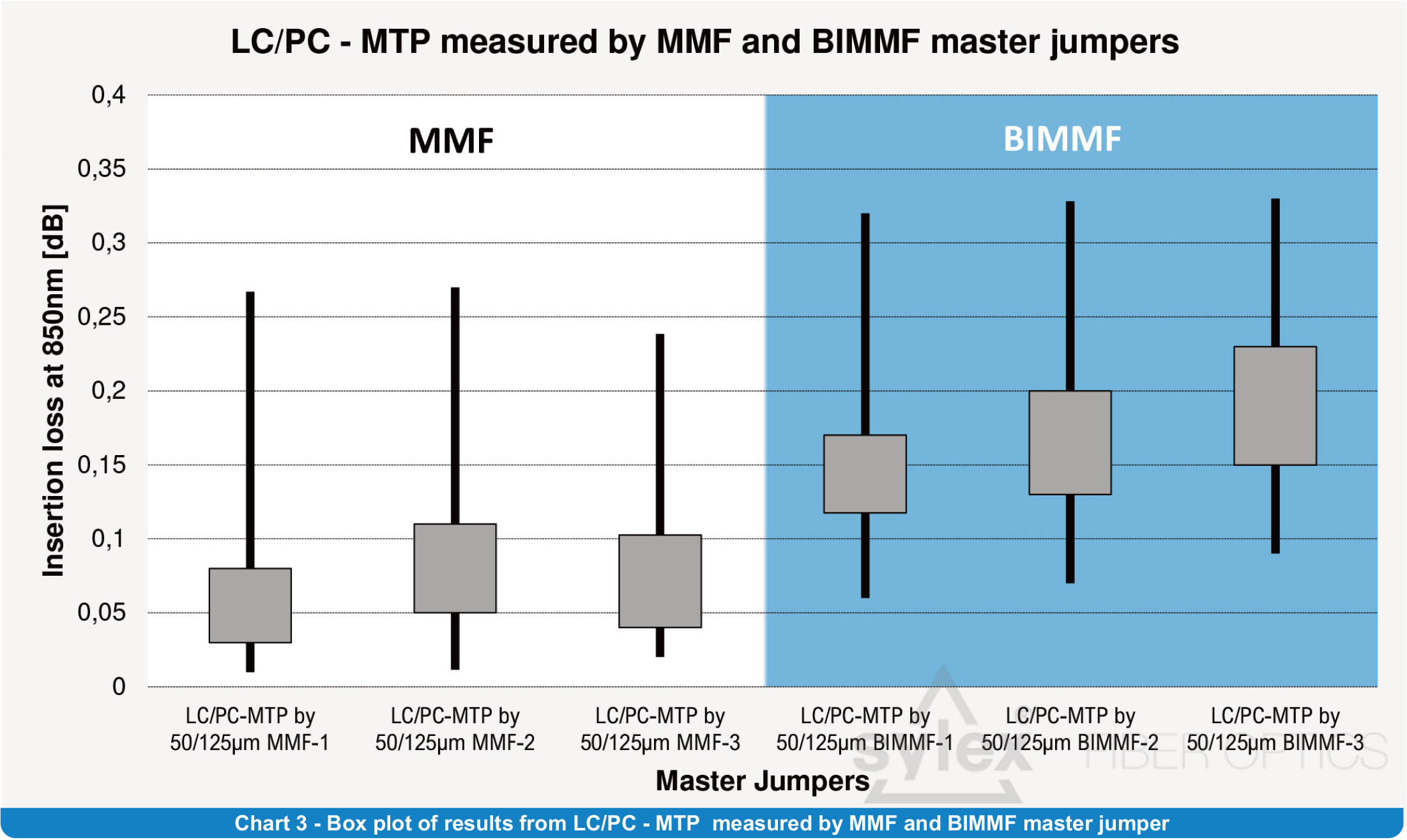

LC/PC to MTP fanout measured by MMF and BIMMF master jumpers

Tested product:

• 6xLCD/PC – 1xMTP(F) 12F 50/125µm BIMMF direct split 0.34m

Master jumper:

• 1xMTP(M) – 1xMTP(M) 12F 50/125µm BIMMF trunk 3.0m

• LC/PC – SC/APC 50/125µm MMF simplex jumper 3.0m

• LC/PC – SC/APC 50/125µm BIMMF simplex jumper 3.0m

Measurement method:

• Measured according to IEC 61280-4-1 annex A, one cord reference method

Equipment used:

• JGR MS12001 system

For this test a combination of LC and MTP connectors was chosen. LC and MTP connectors were terminated on 50/125µm BIMMF. Because the channel value was measured in this test, two master jumpers were used during measurement. The first master jumper containing one fibre was referenced before measurement. The second master jumper containing multiple fibres was not referenced. During the measurement, the first master jumper was connected in front of the DUT and the second master jumper was connected after the DUT. Two different fibre types (50/125µm MMF and 50/125µm BIMMF) were used in single-fibre master jumpers that were used for this test, but only 50/125µm BIMMF fibres were used in multi-fibre master jumpers. This was done to change only one condition while switching from 50/125µm MMF to 50/125µm BIMMF. The initial conditions stayed the same for all tests. This test was performed according to IEC 61280-4-1 annex A, one cord reference method. Around 270 values were measured by each master jumper. On average, the best results were obtained by master jumpers with 50/125µm MMF. Values obtained by BIMMF are 118% higher than the value obtained by MMF. More detailed results are shown in chart 3, where it can be seen that there was slightly higher dispersion in insertion loss values obtained by BIMMF. All results obtained by BIMMF are higher than the ones obtained by MMF master jumpers.

Conclusion

Although the IEC 61280-4-1 standard allows the use of MMF and BIMMF in master jumpers and their mutual exchange, at first glance it can be seen that they are different fibres. BIMMF have one more extra layer around the core. From the point of view of geometry, this layer has no effect, but according to the results of IL measurement, there is a difference between the measured values obtained with master jumper with MMF and with master jumper with BIMMF. Tests have shown that if the DUT contains BIMMF, the use of the same fibre type in the master jumper will give higher insertion loss than the master jumper with legacy MMF that has been recommended by the IEC standard in the past. These tests showed that this difference can be up to 0.19dB. Thus, although the new revision of the IEC standard allows the use of MMF or BIMMF in master jumpers, it must be taken into account that these fibres have various properties and behave differently.

Juraj Kadlec – Metrology Engineer – Contact

Juraj Kadlec is metrology engineer at Sylex. He started as a project engineer with specialization for multi-fiber MTP technology. He widened his activities to fiber optics sensors. Later, he participated in technology and engineering activities responsible for transferring customer ideas to the final products. Later, he held the role of industrial engineer and was responsible for product documentation. In his current position he is responsible for metrology, measured data analysis, optimizing all instruments used for measuring, their maintenance and service.